Description

Conductive PTFE Belt YS9037BJ

- Conductive PTFE Belt YS9037BJ, 0.37mm Anti-static release sheet & belt.

- Anti-static PTFE Fiberglass Fabric is coated with specially formulated black PTFE, these fabrics eliminate static electricity during operation,

- Static can be created by friction or other connection, it will collect electric and dust which may destroy electrical component parts, and it will affect the release due to the electrostatic adsorption.

- This conductive PTFE coating fiberglass fabric offers excellent thermal conductivity to dissipate surface static, it is widely used in apparel, electron industry as conveyor belts or release sheet.

Properties of Conductive PTFE Belt YS9037BJ

Strong tensile strength and dimensional stability

High chemical resistant

High dielectric strength, and Resistance to HF

Reusable and has long lifetime

Continuous working from -70°C to +260°C

Resistance to microwaves, UVs and IRs

Easy to release, super Non stick,Low friction and very smooth

Excellent belting material

Specifications of Teflon conductive fiberglass fabric YS9037BJ

| Properties | Metric | Imperial |

|---|---|---|

| Standard width Please ask for other widths | 1000, 1250, 1500, 2000, 2600 mm | 39.5, 49.3, 59.1, 78.8, 102.4 inches |

| Thickness | 0.37 mm | 0.015 inches |

| Coated weight | 730 g/m² | 21.5 oz/yd² |

| PTFE content | 60 % | 60 % |

| Surface resistance | 10^7 to 10^5 OHMS/m² | 10^7 to 10^5 OHMS/m² |

| Tensile strength | 540 N/cm Warp | 308 lbs/inches Warp |

| 508 N/cm Warp | 290 lbs/inches Fill | |

| Temperature resistance | -73 to +260 °C | -100 to +500 °F |

Click here to download the TDS of YS9037BJ-ESONE

Applications of PTFE/Teflon conductive glass fabric YS9025BJ

Garment Industry

Anti static PTFE fabric YS9013BJ is also used on TFT-LCD module and PDP module process, especially in ACF bonding process of TFT-LCD module, this fabric’s function is shock-absorber of bonding tool, eliminate static electricity during operation and protecting glass panel from breaking damage cause by particle and unbalance of PCB size.

Thermal Lamination Manufacturing

- Thermal lamination is a typical process for producing lightweight and high performance composited material in automotive industry.

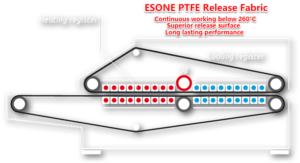

- ESONE PTFE coating fiberglass fabric is a important aid for the lamination operations of decorative material, organo sheet, molten polymers, adhesives and others. These PTFE coated fabric is used as release sheet or conveyor belt due to the excellent temperature resistance, abrasion resistance and easy release surface. ESONE release solutions will ensure the excellent surface of finish product and maximum the output & machine productivity.

- ESONE defect free and smooth PTFE coated fabric offer long lasting release property, we are your reliable partner for high performance product.

What can be made by using ESONE PTFE coated fabric :

- Dashboards, Door Carrier, Door Wells ,Glove Compartments, Parcel Shelves, NVH Parts

Rubber extrusion and curing

- ESONE Teflon coated glass cloth are a perfect solution for the rubber extrusion and curing line. Our product widely used in the manufacture of rubber profiles, ESONE PTFE belts can continuous working below 260°C and offer excellent release during curing and cooling of PVC, PU, PE or others.

- The non stick surface means that nothing will be left on the Teflon belt, this belt will transfer rubber through the microwave oven or electric oven for curing process and the rubber will has excellent smooth surface.

Reviews

There are no reviews yet.