Description

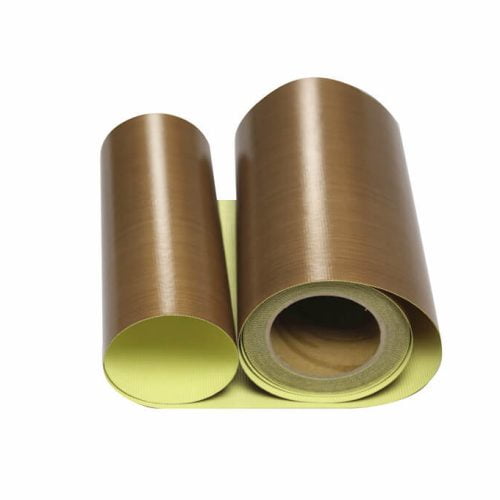

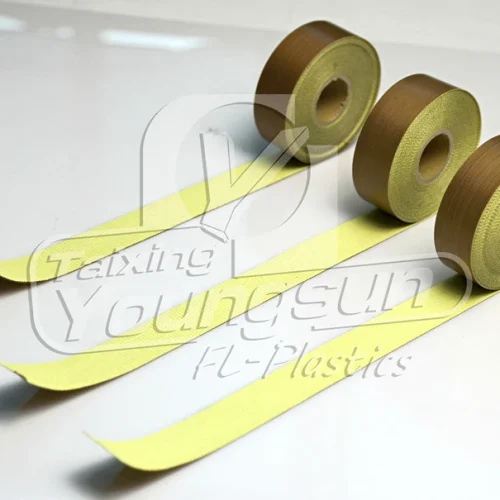

Teflon Adhesive Premium Series, high quality PTFE coated fabric

- Teflon Adhesive premium series is using high quality PTFE coated fabric as basic fabric, after chemical treated one side of PTFE, it will be coated with high quality Silicone pressure adhesive, which can resist heat up to 260°C and offer long lasting performance.

- Yellow textured PVC release liner is applied to the adhesive surface for ease of application and protection long lifetime of fresh adhesive.

Property of PTFE coated adhesive fabrics

Teflon adhesive contain non stick PTFE coated surface and heat resistant adhesive, like silicone PSA or acrylic adhesive, that allow for easy release, superior mechanical strength, long lifetime and dimensional stability.

PTFE coated tape with silicone PSA is the best solution for high request applications, which has requirement for continuous and efficient processing, excellent bonding strength and long lasting performance at high temperatures (up to 500˚F / 260˚C).

The properties of PTFE coated tape with silicone PSA is as follows.

Continuous working from -70°C to +260°C

Good mechanical strength

High dielectric strength, and Resistance to HF

Non-stick surface, good self-cleaning

Flame Resistant

Specifications of PTFE adhesive fabric Premium Series

| Product | Product Category | Coating |

|---|---|---|

| PTFE GLASS FABRIC SELF ADHESIVE | PREMIUM SERIE | SILICONE PSA |

| PTFE Adhesive Fabric Premium Series | ||||||

|---|---|---|---|---|---|---|

| Style | Standard Width(mm) Please ask for other widths | Backing Thickness (mm) | Total Thickness (mm) | Weight (g/m2) | Adhesive (N/cm) | Tensile Strength Warp/Fill (N/cm) |

| YS7008AJ-ESONE | 1000, 1250 | 0.08 | 0.13 | 155 | 4.4 | 104/98 |

| YS7013AJ-ESONE | 1000, 1250 | 0.13 | 0.18 | 270 | 5.4 | 240/200 |

| YS7015AJ-ESONE | 1000 | 0.15 | 0.20 | 316 | 5.6 | 240/200 |

| YS7018AJ-ESONE | 1000 | 0.18 | 0.23 | 370 | 5.6 | 320/302 |

| YS7020AJ-ESONE | 1000 | 0.20 | 0.25 | 410 | 5.7 | 280/256 |

| YS7025AJ-ESONE | 1000 | 0.25 | 0.30 | 530 | 6.0 | 460/400 |

| YS7030AJ-ESONE | 1000 | 0.30 | 0.35 | 625 | 6.2 | 680/640 |

Applications of Teflon adhesive

Aircraft Composites Manufacturing

ESONE PTFE coated fabric is used in the manufacturing of composite aircraft components, like mold release tape, vacuum bagging bleeder cloths.

Mold release tape is applied directly to the mold, allowing for a clean and easy release surface. And the porous PTFE fabric provides excellent release and is used as breather fabrics, allowing for air and volatiles to escape

Wind Turbine Blades Release

This application also use PTFE porous fabric and PTFE adhesive fabric. We customize PTFE porous fabric with balanced porosity & release property, and has high mechanical strength. For PTFE adhesive fabric, our mold release tape is easy release and has high mechanical strength, so that it can be reused many times easily.

Automotive Composites Manufacturing

-PTFE Release sheet for lightweight plastic/polymer processing like SMC, GMT and RMT.

-PTFE Release sheet for lightweight automotive components like front ends, underbody trims, door carrier, parcel shelf and auto seat.

-PTFE Release sheet with adhesive for vehicle cord fabric lamination.

-PTFE Bleeder cloths and PTFE mold release tape for carbon fiber car hood.

Electrical Insulation

Youngsun PTFE coated cloth is used for electrical insulation such as aerospace wire wrapping and electrical coil and phase insulation.-Our PTFE Fabric has excellent mechanical strength, high dielectric constant, strong chemical resistance and heat resistant to 500°F/260°C.

Youngsun PTFE fabrics are also used as linings for the coils of superconducting magnets in order for reducing noise and vibration.

FPCB CVL Lamination

Youngsun PTFE coated fabrics are used as release liner for CVL (coverlay) lamination or quick lamination, since our material has high mechanical strength and offers excellent release and non-stick property.

Excellent smooth, easy release and defect free PTFE fabric will maximum the output in FPCB manufacturing process.

Plastic bag manufacturing

Youngsun PTFE belting is used as conveyor belt to prevent polyethylene film sticking on the surface. Our belt last long, offers quick replace and easy to use.

Our belts for food packaging and sealing are available in tear resistant and porous versions for flexible packaging.

Packaging and Sealing

Youngsun PTFE belting is used as conveyor belt to prevent polyethylene film sticking on the surface. Our belt last long, offers quick replace and easy to use.

Our belts for food packaging and sealing are available in tear resistant and porous versions for flexible packaging.

PVC Window and Door welding

PTFE coated fiberglass cloth has excellent no stick surface and can resist heat up to 260°C, which can prevent melted PVC from sticking on welding platens. ESONE’s product is workable for all kinds of welding process, including RF and microwave systems.

Due to the non stick surface of PTFE Adhesive Sheet, ESONE product is used in Dyeing industry, in order for offering heat resistant and non stick surface.

Due to the non stick surface of PTFE Adhesive Sheet, ESONE product is used in Dyeing industry, in order for offering heat resistant and non stick surface.

Reviews

There are no reviews yet.